Top Incremental Rotary Encoders Supplier with High Precision and Fast Delivery

Find trusted incremental rotary encoders suppliers offering high resolution, customizable options, fast delivery, and reliable industrial quality.

Read More

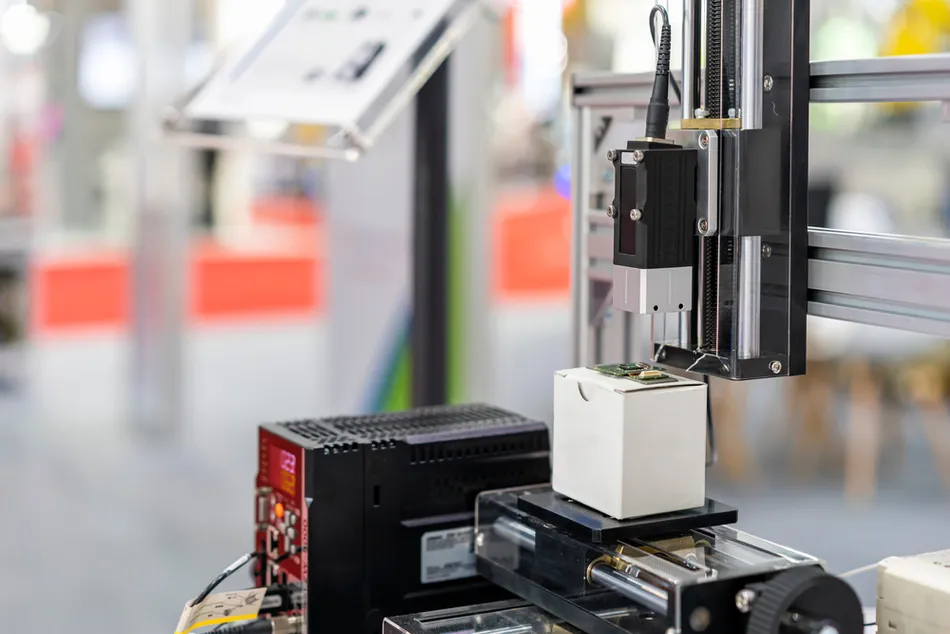

Have you ever wondered how machines “know” their position or speed? The answer often lies in a key component—the encoder. Encoders are sensors that convert mechanical motion into electrical signals, acting as the “hidden heroes” of modern industrial automation and smart manufacturing. Whether it’s the precise positioning of a robotic arm or the efficient operation of a CNC machine, encoders play an indispensable role.

In this guide, we’ll take you on a deep dive into what encoders are, how they work, their types, and their applications. Whether you’re new to the industry or a procurement manager searching for the right encoder, this article will provide you with practical knowledge and selection tips. Let’s unveil the mystery of encoders and explore how they drive the future of industrial automation.

The core function of an encoder is to “sense” the movement of mechanical parts and convert it into electrical signals that control systems can recognize. Simply put, it’s like the “eyes” of a machine, telling the system, “I’ve rotated this much” or “I’ve moved this far.”

These signals can be read by PLCs, motion controllers, or robotic systems, enabling precise control of mechanical movement.

Encoders come in many varieties. Based on working principles and output signals, they can be divided into several main categories:

| Type | Description | Typical Applications |

|---|---|---|

| Rotary Encoder | Detects the rotation angle or speed of a shaft; the most common type | Motor feedback, robotic joints, CNC machines |

| Linear Encoder | Measures linear displacement; ideal for precision length measurement | Conveyor positioning, cutting machines, measuring instruments |

| Absolute Encoder | Each position corresponds to a unique code; remembers position even after power loss | Robots, multi-axis systems, automation equipment |

| Incremental Encoder | Calculates position via pulse count; needs recalibration after power loss | Speed measurement, simple position feedback |

| Optical Encoder | Uses optical sensors to read marks on a code disk | High-precision scenarios |

| Magnetic Encoder | Detects position via magnetic field changes; strong anti-interference | Harsh environments, industrial automation |

Understanding the characteristics of different encoders helps you select the most suitable product for your needs.

Encoders are used in a wide range of fields—almost anywhere precise motion control is needed:

Industrial Automation & CNC Machines

Encoders provide feedback for precise tool positioning and path control, improving machining accuracy and efficiency.

Motor Feedback & Speed/Position Control

Encoders deliver real-time speed and position data for motors, ensuring smooth and controlled movement.

Conveyor Speed & Position Monitoring

They ensure synchronized and accurate material transport, preventing production line stoppages.

Multi-Axis Control & Robotic Positioning

Encoders provide precise angle feedback for robotic joints, enabling complex movements and efficient collaboration.

Length Measurement & Cutting Control

In cutting equipment, encoders enable “cut-to-length” functions, ensuring accurate cutting dimensions.

These applications not only boost production efficiency but also ensure product quality—making encoders the foundation of modern smart manufacturing.

With so many encoder products on the market, how do you pick the one that fits your needs? Here are some key points:

Choosing the right encoder ensures stable equipment operation and reduces future maintenance costs.

The benefits of encoders go far beyond the basics:

With the advancement of Industry 4.0 and smart manufacturing, encoders are becoming even more essential.

Encoders serve as the “nervous endings” of industrial automation, giving machines the ability to “sense.” They enable precise motion control and are driving the rapid development of smart manufacturing. Whether you design production lines or make purchasing decisions, mastering encoder knowledge will help you make smarter choices.

If you’re looking for a high-quality encoder supplier, visit our website (https://sensyorcoder.com) for more product information and custom solutions. Contact us now for expert advice and a free quote—let’s take your automation project to the next level!

position-related electrical signals. Sensors, in general, measure a wider range of physical quantities such as temperature and pressure.

Encoders connect to PLCs via standard interfaces (such as TTL, HTL, SSI, PROFINET, etc.). The PLC reads encoder signals and performs motion control accordingly.

Ensure the encoder shaft is concentric with the measured shaft to avoid mechanical stress. Pay attention to protection level and environmental adaptability. Wire and configure parameters correctly.

Common faults include no signal output, signal interference, and mechanical jamming. Troubleshooting involves checking power supply, wiring, mechanical installation, and signal quality.