Incremental Optical Encoders Guide Features Working Principles and Applications

Explore high-precision incremental optical encoders with advanced quadrature signals resolution durability ideal for industrial motion control applications.

Read More

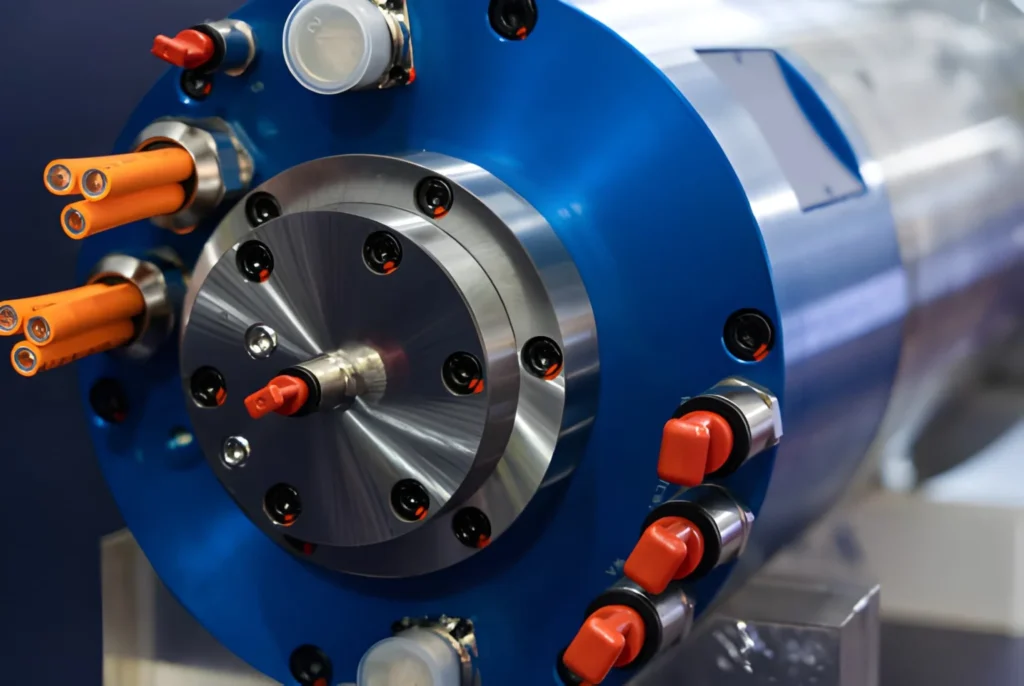

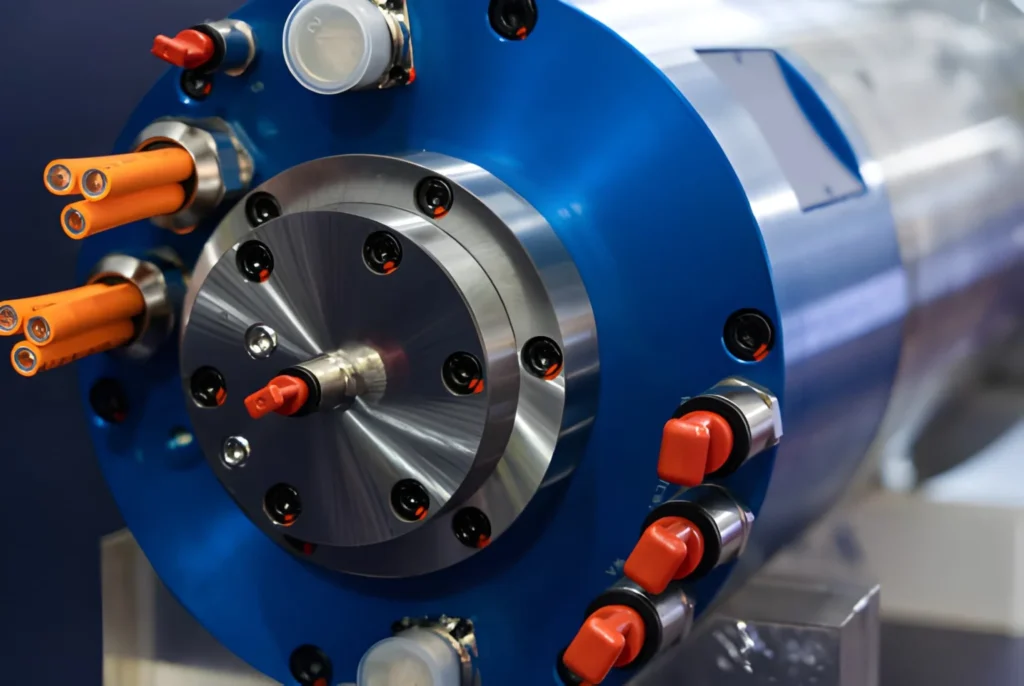

Incremental rotary encoders convert mechanical rotation into electrical signals that machines use to track position and speed. The core mechanism involves a rotating disk paired with a stationary sensor setup.

As the disk rotates, the alternating opaque and transparent (or magnetic) sections modulate the sensor input.

Each time the sensor detects a change—whether a light beam blocked or a magnetic field shift—it generates a square wave pulse. These pulses represent increments of movement.

Channel A & B – Quadrature Encoding

Channel Z – The Index Pulse

In , incremental rotary encoders use a rotating disk and stationary sensor mask to generate pulses that machines interpret via channels A, B, and Z, enabling accurate speed, direction, and position tracking.

When deciding between incremental rotary encoders and absolute encoders, understanding their core differences is key. Incremental encoders generate pulses as the shaft rotates, but they lose position data when power is cut. That means after a power loss or system reset, the controller cannot know the exact position until the encoder re-calibrates — unlike absolute encoders, which keep track of the exact angular position at all times thanks to unique coding on their disks.

Cost and complexity also play a big role in choosing incremental encoders. They tend to be more affordable and have simpler wiring setups compared to absolute encoders. This makes incremental encoders the industry standard for speed measurement and relative positioning, especially when precise position hold-through power cycles isn’t critical.

Common best use cases for incremental encoders include conveyor belts where speed feedback is enough, motor speed control in industrial automation, and cut-to-length applications where relative movement tracking is required. For these tasks, incremental encoders provide reliable rotary pulse generation without unnecessary complexity or cost.

If you’re interested, Sensyor offers a range of incremental encoders, such as the GOS5008B Rotary Encoder designed for industrial feedback loop control with options that fit a variety of shaft encoder specifications.

When choosing an incremental rotary encoder, key specs affect both performance and compatibility. Here’s what to focus on:

| Type | Description | Best Use Case |

|---|---|---|

| Open Collector (NPN/PNP) | Simple output for PLCs, needs pull-up resistors | Standard industrial automation sensors, easy PLC hookup |

| Line Driver (RS422) | Differential signals for noise immunity and long distance | Harsh environments, long cable runs |

| Push-Pull (HTL) | Supports wide voltage range, robust and versatile | Versatile installations, moderate distances |

For more details on compact rotary encoders and robust options, check out the GOS25C Rotary Encoder series from Sensyor. This line offers ideal balance in size, resolution, and output types for precise motion control feedback.

The GOS25C Series from Sensyor perfectly shows why compact incremental rotary encoders are crucial for tight spaces like robotics and miniature motor applications. Its small φ25mm housing lets you fit a high-quality shaft encoder specification right where bulky sensors just won’t do. This compact size ensures seamless integration without sacrificing performance, making it a go-to for precision motion control feedback in space-constrained environments. For a closer look, check out the detailed specs on the GOS25C Rotary Encoder.

Durability is critical for industrial automation sensors, and Sensyor designs the GOS25C with robust IP ratings that protect against dust and moisture, extending service life even in tough factory settings. Its rugged build includes shock resistance to withstand sudden impacts, plus bearing load capabilities that ensure reliable angular position sensing during continuous operation. These features reduce downtime and maintenance, vital for demanding conveyor belt or motor speed feedback systems.

When it comes to performance, the GOS25C incremental encoder shines with high-frequency response and stable output signals, critical for precise feedback loop control. Its push-pull output circuit supports clean A/B/Z phase output pulses, helping minimize noise and jitter for accurate pulses per revolution (PPR) detection. Whether you need high-resolution rotary pulse generation or reliable speed and direction measurement, the GOS25C delivers consistent results under heavy industrial use.

In industrial automation, no two machines are exactly the same. While standard incremental rotary encoders are reliable, they often fall short when precise shaft sizes, cable lengths, or pulse requirements are needed for unique control systems. This is where customization becomes critical—off-the-shelf products can’t always meet specific application challenges, especially in tight spaces or specialized feedback loops.

Sensyor understands these nuances and offers tailored solutions to fit diverse industrial needs. Their incremental shaft encoder customization includes:

By choosing customizable incremental encoders from Sensyor, you get a perfect fit that enhances your system’s reliability and performance without the typical compromises of standard encoder specs. For detailed options on precision incremental shaft encoders, explore Sensyor’s incremental encoders customization services.

Proper installation is key to getting the best performance from your incremental rotary encoder. When mounting, it’s crucial to use flexible couplings to connect the encoder shaft to the motor or machine shaft. This helps prevent bearing damage caused by shaft misalignment or vibrations, ensuring a longer lifespan for your encoder.

For wiring, good shielding practices are a must to avoid electrical noise interference, especially the EMI generated by variable frequency drives (VFDs) and motors. Using shielded cables and grounding them properly reduces signal distortion and keeps your quadrature encoding signals clean. This means more accurate speed and position feedback for your motion control system.

If you need reliable mounting accessories, consider exploring flexible coupling solutions available at trusted providers like Sensyor for hassle-free installation that protects your rotary pulse generator from mechanical stress. Their coupling series offers versatile options tailored for industrial automation sensors.

Maintaining these installation and wiring hygiene standards will significantly improve the stability and lifetime of your incremental encoder’s output signals, crucial for any feedback loop control in industrial applications.