Incremental Optical Encoders Guide Features Working Principles and Applications

Explore high-precision incremental optical encoders with advanced quadrature signals resolution durability ideal for industrial motion control applications.

Read More

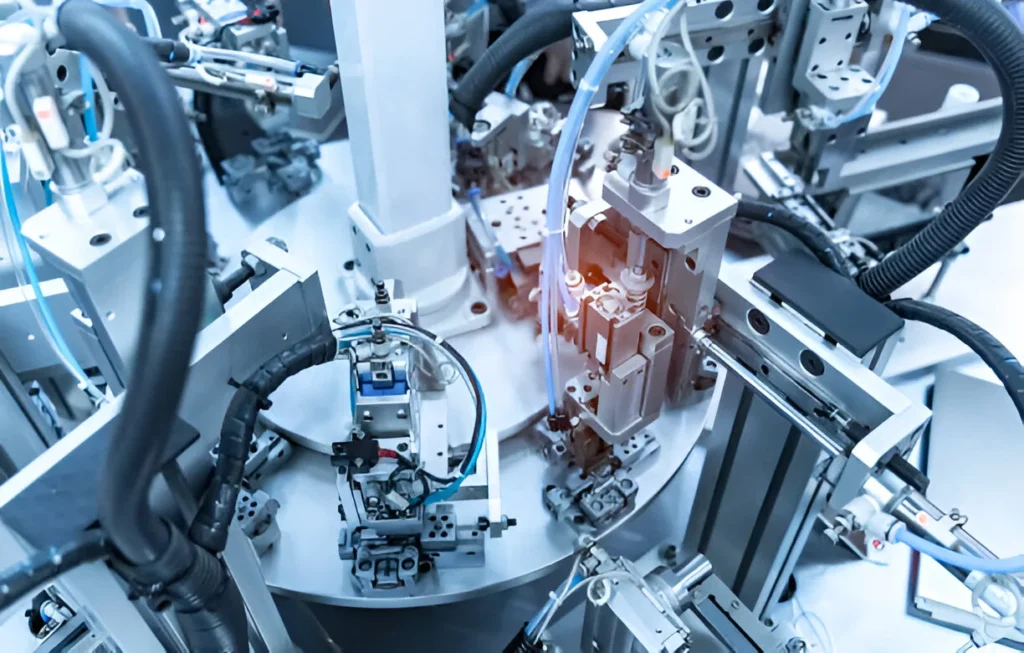

In the world of automation, robotics, and industrial equipment, precision is more than just a goal—it’s a requirement. That’s where the incremental rotary encoder comes in. This small but mighty sensor has become one of the most essential components for modern motion control systems, ensuring that machines move with accuracy, consistency, and reliability.

But what exactly is an incremental rotary encoder, and how does it compare to other encoders like absolute or optical ones? More importantly, how can it boost the performance and efficiency of your automation setup? Let’s dive deeper into the technology, applications, and benefits of using incremental rotary encoders.

An incremental rotary encoder is a type of position sensor that measures the angular movement of a rotating shaft. Unlike an absolute encoder, which provides a unique code for each shaft position, the incremental type tracks motion by generating electrical pulses corresponding to the rotation.

Every time the encoder shaft turns, it produces a series of digital signals (A, B, and sometimes Z channels) that can be interpreted to determine speed, direction, and position change.

Typical Encoder Signal Comparison

| Encoder Type | Output Signal | Position Tracking | Cost Efficiency |

|---|---|---|---|

| Incremental Rotary Encoder | Pulse-based (A, B, Z channels) | Relative position | Cost-effective |

| Absolute Encoder | Unique digital code per position | Absolute position tracking | Higher |

This pulse-based system is why incremental encoders are often used in motor feedback, linear actuators, conveyor systems, and robotics — they deliver real-time motion feedback at an affordable cost.

Think of an incremental encoder as a digital eye that constantly watches and counts how far a motor shaft spins. Inside the encoder, a rotating code disk with precisely spaced lines interacts with a light source (in optical encoders) or magnetic sensors (in magnetic encoders). Each time the shaft moves, those lines interrupt the light or magnetic field, creating pulses that are sent to a controller or PLC.

By counting these pulses, the system can calculate:

Some incremental encoders also feature an index pulse, also known as the Z-channel, which marks one specific point per revolution. This signal helps machines establish a zero or home reference point during startup calibration.

Pulse Signal Example

| Channel | Function | Use Case in Control System |

|---|---|---|

| A | Primary pulse signal | Position tracking and speed measurement |

| B | 90° phase-shifted pulse | Direction detection |

| Z | Index pulse | Reference or home position detection |

When selecting an incremental rotary encoder, you’ll encounter two primary types: optical and magnetic. The choice depends largely on your application environment and required precision.

Optical encoders use light beams and gratings to generate signals with extremely high resolution—perfect for CNC machinery or semiconductor manufacturing. However, they can be sensitive to dust, vibration, or oil contamination.

Magnetic encoders, on the other hand, use Hall-effect sensors and magnetic fields to detect rotation. They’re ideal for outdoor or harsh industrial environments where dirt or moisture may be present.

| Feature | Optical Incremental Encoder | Magnetic Incremental Encoder |

|---|---|---|

| Resolution Range | Up to tens of thousands PPR | Moderate, up to a few thousand PPR |

| Environmental Resistance | Low | High |

| Cost | Higher | More affordable |

| Output Stability | Very stable | Stable even under vibration |

If your machinery operates in a clean, high-precision environment, optical encoders perform best. But if rugged durability matters more, a magnetic incremental rotary encoder may be the smarter choice.

Incremental encoders are everywhere—often hidden inside motors, factory machines, or medical equipment. Their versatility lies in their ability to measure both position and motion in real time.

Example Application Overview

| Industry | Function | Benefit |

|---|---|---|

| Robotics | Joint motion feedback | Smooth, coordinated operation |

| Textile Machinery | Yarn tension and positioning | Improved production consistency |

| Packaging Equipment | Roller speed control | Accurate cutting and labeling |

| Renewable Energy | Turbine control feedback | Optimized energy capture |

If your automation project needs precise rotary feedback, consider integrating an incremental rotary encoder. It provides a balance of simplicity, accuracy, and affordability often unmatched by other sensor types.

This comparison is one of the most common questions engineers ask when selecting an encoder. The incremental rotary encoder provides relative motion feedback, which means it only knows how far something has moved from a reference point, not the exact position upon power loss.

An absolute rotary encoder, by contrast, retains its positional data even after shutdown, because each shaft angle corresponds to a unique digital code.

So which one suits your application?

| Criteria | Incremental Encoder | Absolute Encoder |

|---|---|---|

| Data Type | Relative | Absolute |

| Power Cycle Memory | No | Yes |

| Cost | Lower | Higher |

| Wiring Complexity | Simple | More complex |

| Use Case Example | Conveyor motor feedback | Robotic arm calibration |

If your machinery frequently restarts and can easily re-home, an incremental rotary encoder will be a reliable and cost-efficient choice. If you need position memory after power loss, absolute types might be worth the higher investment.

Installing an incremental encoder correctly is crucial for reliable operation and signal integrity.

❶ Align the shaft carefully: A misaligned shaft can cause bearing wear or pulse noise.

❷ Use shielded cables: Prevents EMI interference especially in high-frequency environments.

❸ Secure the mounting base: Vibrations can distort the output signals.

❹ Calibrate the zero position: Set the reference index pulse (Z-channel) to ensure synchronization.

❺ Choose proper output type: Decide between open collector, push-pull, or line driver output based on your PLC input requirements.

Output Type Comparison

| Output Type | Description | Best Application Environment |

|---|---|---|

| Open Collector | Simple, cost-effective output signal | Short cable runs, low EMI environments |

| Push-Pull | Dual voltage output for better noise immunity | Moderate-length installations |

| Line Driver | Differential output, high noise immunity | Long-distance or high-noise systems |

Need help selecting or customizing your incremental encoder setup? Feel free to contact our technical team for guidance or to request a detailed quote—we’ll help you find the right encoder for your system.

The incremental rotary encoder continues to redefine precision motion control with its simplicity, cost-effectiveness, and adaptability. Whether you’re upgrading an existing automation line or designing new industrial equipment, understanding how these encoders work will help you unlock better performance and reliability.

They might be small, but their impact on efficiency and accuracy is huge.

If you’re looking for high-quality incremental rotary encoders—optical or magnetic—tailored to your project, get in touch with us today for a competitive quote and technical support.

PPR stands for Pulses Per Revolution, meaning how many digital pulses are generated in one complete shaft rotation. Higher PPR offers finer movement resolution.

Yes. The two-phase output (A and B channels) is offset by 90°, allowing detection of rotation direction based on the signal phase difference.

Absolutely. They are widely used for feedback control in servo systems, ensuring accurate speed and positional tracking.

TTL (5V logic) and HTL (10–30V logic) differ in voltage levels. HTL signals are more robust for long cable distances or noisy environments.

Keep it dust-free, avoid touching internal optical disks, and ensure that magnetic models are not exposed to strong stray fields. Proper maintenance extends encoder lifespan and preserves accuracy.