Incremental Encoder vs Absolute Encoder Features and Uses

Compare incremental encoder vs absolute encoder to choose the best rotary encoder for accuracy speed and reliable position feedback in industrial applications

Read More

When working with motion control systems, you’ve probably encountered the term “PPR” in the specifications of an incremental rotary encoders. But what exactly does PPR mean? And why does it matter so much in applications like CNC machines, robotics, automation, and servo motors? In this post, we’ll dive deep into PPR (Pulses Per Revolution), explore how it affects accuracy and performance, compare different encoder resolutions, and show you what to consider when selecting the right incremental rotary encoder for your system.

An incremental rotary encoder is an electromechanical device that converts rotational motion into a series of digital pulses. These pulses represent incremental changes in position, which can be processed by a controller to determine speed, direction, and position.

They are widely used in:

Unlike absolute rotary encoders, which retain position data even after power loss, incremental encoders only output pulses relative to movement. This makes them simpler and more cost-effective in many motion control applications.

PPR stands for Pulses Per Revolution. It describes how many digital pulses an encoder produces for each full 360° rotation of the shaft. In other words, it’s a measure of the encoder’s resolution — how finely it can measure rotational movement.

For example:

The higher the PPR value, the more precisely the system can detect changes in position or speed. Engineers often use high-PPR encoders for applications requiring precision control, such as robotic arms or servo feedback loops.

You may also come across similar terms like Counts Per Revolution (CPR) or Lines Per Revolution (LPR). Although sometimes used interchangeably, they can differ depending on the manufacturer’s pulse counting method.

| Term | Meaning | Typical Usage |

|---|---|---|

| PPR | Pulses generated per full rotation | Industrial and encoder datasheets |

| CPR | Total counts per revolution after signal quadrature | CNC and motor control systems |

| LPR | Number of lines on encoder disk | Optical encoder terminology |

When choosing your encoder, always check how the manufacturer defines these terms — a 1000 PPR encoder may actually provide 4000 counts per revolution (due to 4X decoding).

The PPR value directly influences system accuracy, speed feedback, and noise immunity. A high-PPR encoder can track tiny movements and provide smooth control, while a low-PPR one is suitable for faster but less precise motion.

Let’s explore how resolution impacts performance:

| PPR Range | Applications | Advantages | Limitations |

|---|---|---|---|

| 100–500 | Basic conveyors, fans, machine tools | Low cost, low latency | Coarse feedback |

| 500–1024 | Mid-range automation, robotics | Balanced precision and speed | Moderate cost |

| 2048–5000 | Servo drives, CNC systems | High accuracy and smooth speed control | Higher cost, more signal noise |

Choosing the right PPR is all about balancing resolution and speed requirements. For example, if your system spins at high RPMs, too high a PPR may overwhelm the controller with pulses.

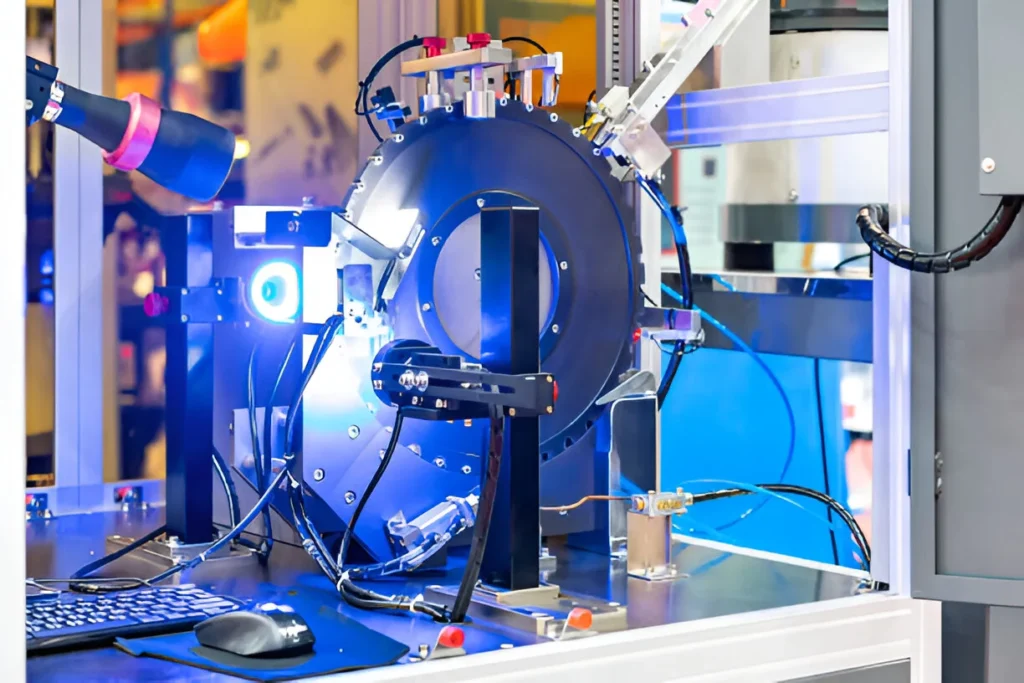

Inside every incremental encoder lies a simple yet elegant mechanism: a rotating disk with transparent and opaque segments, an LED light source, and optical sensors that detect interruptions in the light path. As the shaft rotates, the sensors register light-and-dark transitions, translating them into pulses.

Usually, an encoder has two output channels (A and B), spaced 90° apart. This setup allows determination of:

Some encoders include a third Z-channel or index pulse, which provides a reference once per revolution — helpful for homing functions.

For example, a 1024 PPR incremental encoder with quadrature output generates 4096 counts per turn when decoded (4x mode). That means each count represents about 0.088° of shaft rotation — incredibly precise feedback.

When you integrate an incremental rotary encoder with a servo motor, your system gains real-time motion feedback that ensures high repeatability and minimal vibration. The result: stable performance in complex automation environments.

When selecting an incremental rotary encoder, the following factors help determine the ideal PPR value:

Here’s a quick selection guide:

| Application | Recommended PPR | Output Type |

|---|---|---|

| Conveyor systems | 200–500 | Open collector |

| Stepper motors | 500–1000 | TTL |

| Servo feedback | 1000–5000 | Differential (RS422) |

| Robotics and CNC | 2048–4096 | HTL or differential |

Need advice on choosing the right model? Contact our technical team or send an inquiry today — we’ll help you match your system with the best high-performance incremental encoder.

Understanding what PPR means in an incremental rotary encoders is fundamental for achieving optimal motion control performance. From servo drives to industrial robots, your choice of resolution impacts how smoothly your machines operate, how accurately they move, and how efficiently they communicate with controllers.

The next time you compare encoders, remember that PPR defines how “smart” your motion feedback can be. Choose wisely to balance accuracy, cost, and system speed.

If you’re currently sourcing incremental rotary encoders or looking for OEM alternatives with specific PPR values, reach out to our support team today — we provide custom encoder solutions tailored to your application needs.

Incremental encoders provide relative position data through pulses, while absolute encoders give a unique position code for every angle — maintaining position even after power loss.

Yes, but note that higher resolution may increase noise sensitivity and processor load. Using mid-range PPR (e.g., 1024) is usually optimal.

Common types include TTL (5V), HTL (10–30V), and differential RS422. Each suits different cable lengths and noise environments.

Use the formula:Pulse frequency = (RPM × PPR) / 60

So, a 1000 PPR encoder at 1200 RPM outputs 20,000 pulses per second.

Look at ambient temperature, vibration, shaft alignment, and IP protection. Encoders used in humid or dusty industries should have at least IP65 sealing.