Incremental Optical Encoders Guide Features Working Principles and Applications

Explore high-precision incremental optical encoders with advanced quadrature signals resolution durability ideal for industrial motion control applications.

Read More

If you’re wondering whether to go with an absolute encoder vs incremental, you’re not alone. Choosing the right encoder can make or break the precision and reliability of your motion control system. Absolute encoders offer instant, unique position data—even after power loss—while incremental encoders excel in cost-effectiveness and high-resolution speed feedback. In this guide, you’ll quickly learn the key differences, advantages, and real-world scenarios that make one better suited than the other. Ready to make an informed choice? Let’s dive into everything you need to know.

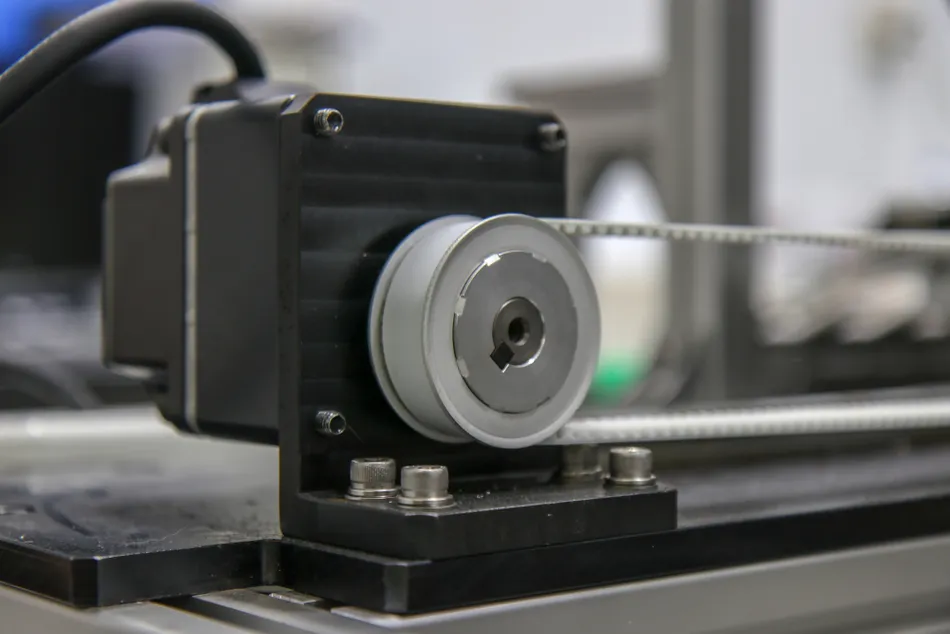

An incremental encoder is a sensor that provides relative position feedback by producing pulses as it moves. Rather than giving a fixed position, it generates signals that indicate how much and in which direction the shaft or object has rotated or moved.

Both types provide reliable incremental signals but vary in noise immunity and environmental resilience.

Incremental rotary encoders are popular for their simplicity, cost-effectiveness, and suitability in systems that can perform homing or zeroing routines.

An absolute encoder provides position feedback by generating a unique code for every specific shaft position. Unlike incremental encoders, which rely on pulses to track movement, absolute encoders output a distinct digital value for each angle or linear position. This means the exact position is known instantly when powered on, without needing to return to a reference point.

There are two main types of absolute encoders: single-turn and multi-turn. Single-turn encoders track position within one rotation (0 to 360 degrees), while multi-turn encoders also count the number of full rotations, making them ideal for applications needing extended range and accurate multi-revolution tracking.

Absolute encoders support various common communication interfaces such as SSI (Synchronous Serial Interface), BiSS, parallel outputs, and fieldbus protocols. These interfaces offer flexibility in integrating with different control systems and support robust, noise-resistant signals that help maintain accuracy in harsh industrial environments.

Because an absolute encoder reports a unique position code, it provides immediate and reliable position feedback right after power-up, eliminating the need for homing sequences and reducing downtime in critical systems. This makes them well-suited for applications where knowing the exact shaft position at all times is crucial.

For a deeper dive into pulse-based relative position tracking, you can explore more about incremental rotary encoders here.

Understanding the differences between absolute and incremental encoders is crucial when selecting the right rotary encoder for your application. Here’s a clear breakdown:

| Feature | Absolute Encoder | Incremental Encoder |

|---|---|---|

| Signal Type | Digital codes (SSI, BiSS, etc.) | Quadrature pulses (A, B, Z) |

| Wiring Complexity | Higher (more wires/interfaces) | Lower (fewer wires) |

| Noise Immunity | Better in noisy environments | More susceptible to noise/pulse loss |

| Cost | Generally higher | Generally lower |

| Power Loss Position Retention | Yes | No, requires homing |

| Size and Integration | Often bulkier or more complex | Simpler and smaller designs |

For those interested in the mechanics of incremental signals, exploring incremental quadrature output helps clarify how they track relative motion efficiently.

By knowing these key differences, you can better match your project needs—whether it’s the immediate position feedback of an absolute encoder or the cost-effective precision of an incremental rotary encoder.

Pros:

Cons:

Pros:

Cons:

Choosing between these two often depends on your application’s priority—whether you need reliable position retention and safety or cost efficiency and speed precision. For detailed insights into incremental rotary encoder advantages, check out this comprehensive guide on the power of incremental rotary encoders in motion control.

Absolute encoders are the go-to choice when your application demands immediate and reliable position feedback without needing to reset or home the system. Consider these scenarios:

| Scenario | Why Absolute Encoder? |

|---|---|

| Robotics & medical equipment | Instant, accurate position on power-up |

| Frequent power interruptions | Position memory retained without homing |

| Safety-critical applications | Avoid risks and time from homing procedures |

| Multi-turn industrial machinery | Continuous tracking beyond one full turn |

For more guidance on choosing the right type, check out our detailed advice on how to choose the right encoders for your B2B project. If you want to explore specific product options, Sensyor’s range of reliable absolute rotary encoders offers excellent quality and customization.

Incremental encoders shine in budget-sensitive projects where speed, velocity, or straightforward positioning is the main focus. Because they offer high-resolution pulse outputs, they excel in high-speed applications like motor velocity control and basic automation systems. Incremental rotary encoders provide precise feedback on movement direction and speed, making them ideal for setups where easy homing routines are possible and position resets on power cycles aren’t a big concern.

Key situations to choose incremental encoders include:

For those looking for dependable incremental rotary encoder solutions suited to industrial automation, Sensyor offers high-quality options designed for precision and durability. You can explore detailed insights into how these encoders perform in industrial settings with their incremental rotary encoder applications in industrial automation and understand the technology behind them on the incremental optical encoder technology page.

In , incremental encoders are often the better fit when you need cost-effective, high-speed position feedback and can accommodate homing routines after power interruptions.

Incremental encoders are widely used in applications where measuring speed, direction, or relative position changes is crucial. You’ll find them in servo motors, conveyor speed monitoring, and CNC machine velocity feedback systems. Their straightforward quadrature signals make them ideal for fast, real-time control tasks, especially where homing routines are manageable.

On the other hand, absolute encoders shine in applications that demand precise, immediate position feedback without needing homing after power loss. They’re common in robotic joints, elevators, wind turbines, and other precision positioning systems in manufacturing. Their multi-turn variants and robust position retention suit complex automation and safety-critical environments.

There’s also a growing trend toward hybrid setups combining both encoder types to leverage the strengths of each. For example, some advanced machinery integrates incremental encoders for high-speed motion control alongside absolute encoders for reliable position tracking and safety assurance.

For linear position sensing needs in these applications, high-quality linear encoders can complement rotary encoders, offering precise feedback in both axes.

In :

Choosing the right encoder—whether absolute or incremental—means balancing several key factors to fit your application’s needs.

For tailored options that cover these considerations, Sensyor offers a diverse range of incremental rotary encoders and absolute encoders like the high-performance GLT10030B rotary encoder designed for industrial reliability and precision.

Sensyor offers a comprehensive range of both incremental rotary encoders and absolute encoders, engineered for precision and reliability in industrial applications worldwide. Our products stand out thanks to high-quality manufacturing processes, ensuring durability and consistent performance even in demanding environments.

We provide extensive custom options tailored to suit specific needs, from unique shaft sizes to specialized output signals like SSI or quadrature. Thanks to our advanced production capabilities, Sensyor delivers competitive pricing without compromising on quality, making us a trusted supplier in the global encoder market.

Beyond rotary encoders, Sensyor also supplies linear encoders, designed for accurate linear position feedback across diverse automation needs. Whether you require a standard encoder or a custom-made solution, our dedicated engineering team supports seamless integration with your systems, including PLCs and drives.

Explore how Sensyor’s encoder manufacturing plant combines innovation and craftsmanship to provide reliable encoders with excellent noise immunity and long-term accuracy, helping you optimize your motion control and positioning systems. For more on how our incremental encoder signals work, you can visit our detailed guide on incremental rotary encoder main output signals and how to identify A, B, Z phases.