Incremental Encoder vs Absolute Encoder Differences and Selection Guide

Discover the key differences between incremental and absolute encoders including performance, cost, and application tips for precise motion control.

Read More

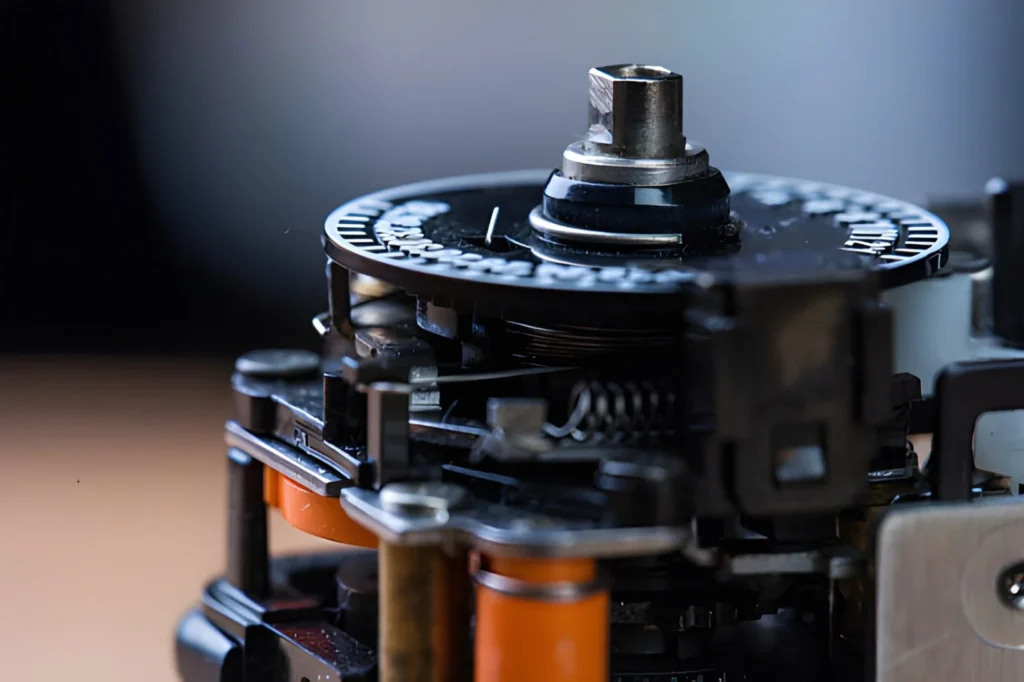

Have you ever wondered how machines track precise movement or position? That’s where incremental encoders come in. These devices convert motion into electrical signals, helping systems measure rotation, speed, or linear displacement accurately and efficiently.

Incremental encoders generate signals that correspond to movement, primarily through:

While both use pulses, the key difference lies in data:

Understanding this helps decide which encoder suits your application best.

Incremental rotary encoders come in various designs to fit different needs:

Why choose incremental encoders? They offer several benefits:

By understanding these basics and differences, you can better decide how incremental encoders fit your project’s requirements, especially when considering customization options to optimize performance.

Off-the-shelf incremental encoders often fall short in meeting unique application needs. Standard models may not fit tight spaces, handle extreme environments, or deliver the exact precision required for certain systems. This is where customization becomes valuable.

| Benefit | Description |

|---|---|

| Improved precision | Tailored resolution and pulses per revolution (PPR) for accurate feedback |

| Better integration | Customized shaft diameter, mounting style, and electrical signals for seamless system fit |

| Enhanced durability | Special housing materials and IP ratings designed for tough conditions |

| Reduced system costs | Minimizes need for additional components or adaptations in your design |

For more on choosing the right incremental encoder based on your environment and needs, check this guide on what environmental factors to consider when choosing an incremental encoder. Customization ensures your incremental encoder fits perfectly, performs reliably, and keeps your system efficient.

Custom incremental encoders come with a wide range of options to fit specific application needs. Here’s a quick breakdown of the main customization areas:

| Feature | Options & Details |

|---|---|

| Resolution & PPR | From low counts up to ultra-high pulses per revolution (10,000+ PPR) for ultra-precise feedback. |

| Mechanical Features | Shaft diameter/type (solid, hollow), housing material (metal, plastic), mounting styles (flange, servo, bearingless), plus IP ratings for dust and water protection. |

| Electrical Outputs | TTL, HTL, push-pull, line driver, open collector, and various voltage levels to match your control system. |

| Signal Configurations | Standard quadrature channels (A/B), index pulse (Z) options, and complementary signals for better noise immunity. For details on quadrature output signals, explore this guide on how to identify A, B, and Z phases. |

| Additional Features | Programmable resolutions, commutation tracks for motor control, different cable or connector types, and extended operating temperature ranges. |

| Technology Choice | Optical encoders offer high accuracy and resolution, while magnetic encoders provide increased durability and resistance to harsh environments. Choosing between these depends on your performance priorities. |

These customization options allow you to optimize your incremental encoder for precision, environment, and integration with your existing systems, ensuring you get the most reliable and efficient feedback solution.

At sensyor, customizing your incremental encoder starts with a straightforward process designed to meet your exact needs. First, we begin with an initial consultation to understand your application requirements and define key specifications like resolution, shaft type, and output signals.

Next, we move to specification definition, where details such as pulses per revolution (PPR), mechanical features, and housing options are finalized. Following this, we develop prototypes to validate design and performance. These prototypes undergo rigorous testing to ensure reliability before moving into full production.

We understand that time and cost matter. sensyor offers competitive lead times and flexible minimum order quantities to suit businesses of all sizes. Because all our manufacturing happens in-house, we maintain tight quality control and enable quick design iterations—meaning faster delivery without sacrificing precision.

To support your project from start to finish, sensyor provides easy-to-use product configurators, detailed technical datasheets, and responsive engineering support. This comprehensive approach ensures your custom incremental encoder matches your exact operational needs, whether for rotary or linear applications, and comes backed by expert guidance every step of the way.

Explore sensyor’s precision components like our CY7 high-frequency counter to complement your customized incremental rotary encoder system.

Customized incremental encoders play a crucial role across various industries where precision and reliability matter. In industrial automation and robotics, these encoders provide accurate position and speed feedback, helping machines perform repeatable, high-speed tasks with confidence. Their adaptability makes them ideal for tailored solutions in complex robotic arms and automated assembly lines.

For motor feedback in servo and BLDC systems, customized incremental rotary encoders optimize performance by matching exact resolution and signal output requirements. This ensures smooth motor control and efficient operation, especially in applications with strict speed and torque demands.

In CNC machinery, conveyor systems, and packaging equipment, tailored encoders improve accuracy and reliability, fitting unique shaft sizes and housing constraints while withstanding harsh operational environments. Custom features like specific pulses per revolution (PPR) and IP-rated housings enhance durability and precision in these demanding setups.

Medical devices and renewable energy sectors also benefit from customized incremental encoders designed to meet strict standards and rugged conditions. For example, vibration-resistant encoders with specialized sealing protect sensitive equipment in wind turbines or diagnostic machines.

Real-world case studies highlight how custom incremental encoders deliver measurable performance gains: enhanced precision, longer service life, and better integration, cutting overall system costs. When off-the-shelf solutions fall short, customized encoders unlock new potential in your equipment, making them indispensable components across critical applications.

For more insights into the role of incremental encoders in automation, check out this detailed guide on incremental rotary encoder applications in industrial automation.

Choosing the right partner for incremental encoder customization is crucial to get the best results for your project. Start by evaluating key factors such as manufacturing expertise, relevant quality certifications, supply chain reliability, and clear pricing transparency. These ensure you get a product that meets your standards without unexpected delays or hidden costs.

When comparing suppliers, focus on their flexibility to adapt to unique needs, commitment to innovation, and the ability to offer long-term technical support. Custom projects often require close collaboration and ongoing adjustments, so a responsive partner is essential.

At sensyor, we stand out with competitive pricing and a proven track record in delivering custom rotary and linear incremental encoders. Our dedicated factory capabilities mean faster turnaround times and consistent quality control throughout the production process. With sensyor, you get the reliability and expertise to support high-performance, tailored encoder solutions that fit your exact application.

For more insights on selecting the right encoder type and supplier, see our guide on how to choose the right encoders for your B2B project.