Optical Incremental Encoder High Resolution Precise Motion Feedback

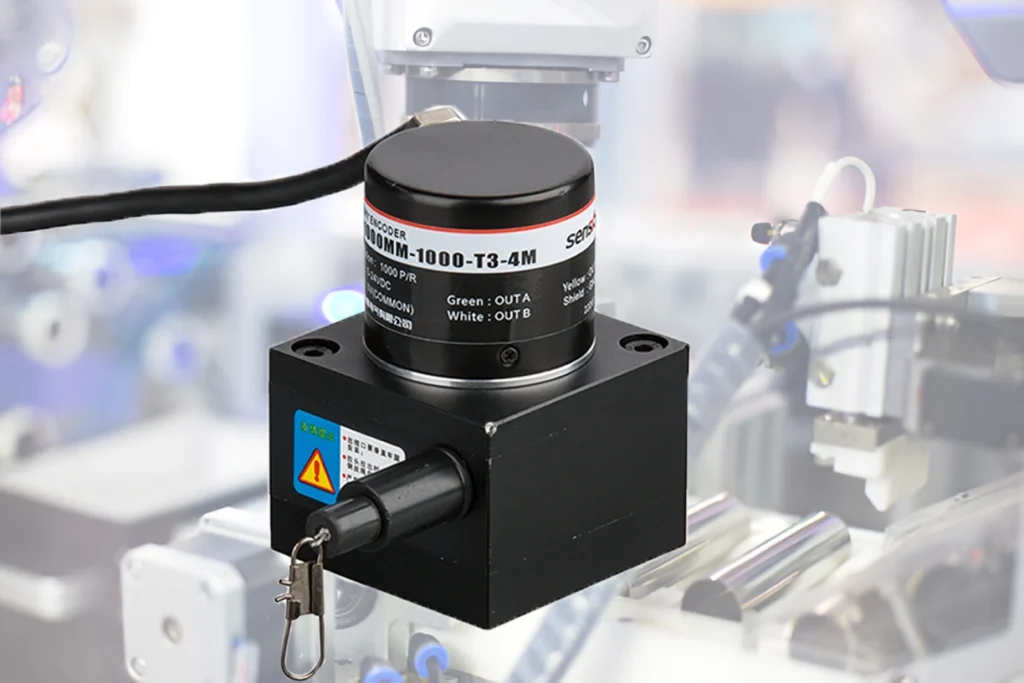

Discover high-precision optical incremental encoders with customizable resolution and rugged design ideal for industrial motion control and automation.

Read More

Incremental encoder are electromechanical devices that measure changes in motion and direction. These units generate A/B digital outputs, with pulses per revolution (PPR) determining their resolution. By encoding the shaft’s angular displacement, they reveal velocity and relative position. Because they provide near-instant feedback, incremental encoders are ideal for high-precision motion control and positioning tasks, such as robotics.

Important limitation: incremental rotary encoder only report changes in position. To obtain absolute position, the encoder signals must interface with external circuitry (controller or counter) that processes and communicates the data. A fixed home reference must be established each time the system powers up or resets, and subsequent position is measured relative to this reference.

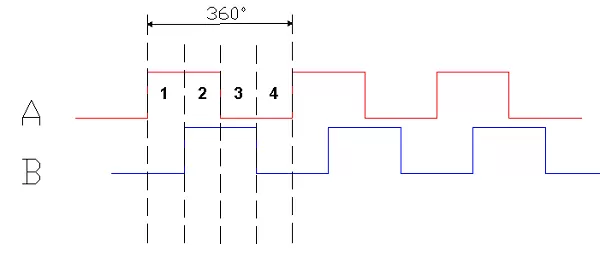

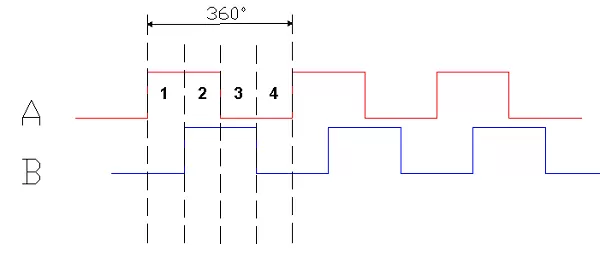

Incremental encoders produce a fixed number of pulses per rotation. The PPR value defines resolution. Pulses appear on two channels, A and B. If direction is not required, only channel A is used; for both speed and direction, A and B are used together.

The A and B channels are offset by 90 electrical degrees, creating quadrature signals. At constant speed, the two square waves are 90 degrees out of phase. Reversing direction changes the relationship between A and B, providing directional data.

An index pulse on the Z channel marks one pulse per revolution. The index signal verifies A/B counts, tracks shaft revolutions, and enables homing by starting from a reference position. The index pulse width can be gated to improve accuracy.

Some models include U, V, W commutation channels aligned with BLDC motor commutation. These signals guide the controller on when to energize motor windings, enabling motion. Quantum Devices offers incremental rotary encoder with built-in commutation signals that align with servo motor channels.

Incremental encoders are widely used with motion controls to locate and direct mechanical systems such as medical equipment, AGVs, machine tools, and other motor-driven devices.

Quantum Devices provides high-performance incremental optical encoders suited to various industrial applications and can tailor configurations to specific needs.

Incremental encoder measure position changes, while absolute encoders report the actual position from a defined reference point. Absolute encoders retain position data after power loss, whereas incremental encoders require a reset or reference on power-up to determine rotation position.

Boost your automation with precise incremental encoder solutions. Contact us now for custom designs and expert advice!

Explore our incremental optical rotary encoder products to view model specifications, or download the line card for a broader overview.

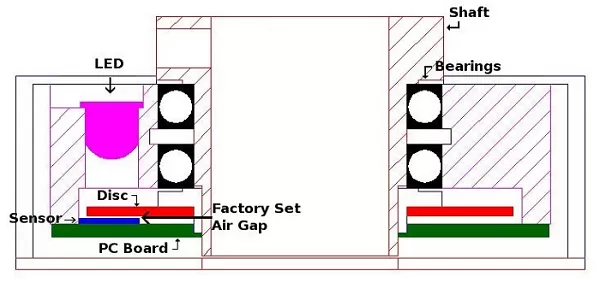

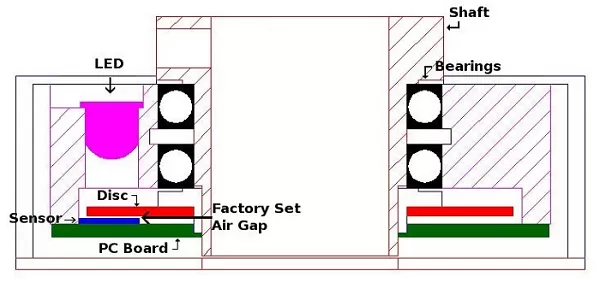

Because incremental encoder do not provide absolute position, their internal design is simple. A typical assembly includes:

Light from the LED passes through the disc onto the photodiode, converting light pulses into electrical signals that feed the PCB and interface with the user. Quantum Devices uses a patented interlaced photodiode to optimize light-to-current conversion. Our in-house component production supports better supply chain and quality control.

Would you like a procurement-facing comparison table tailored to your purchase criteria? If so, I can create one to help quickly identify suitable models.

An encoder that measures changes in position by generating pulses per rotation on A and B channels; a separate Z channel provides an index pulse for reference.

Resolution is defined by pulses per revolution (PPR).

Yes, for absolute positioning you must establish a reference at power-up or reset, unless using an absolute encoder.

A 90-degree phase shift between A and B signals, enabling direction sensing.

U, V, W channels that align with motor commutation signals to drive windings.