Incremental Optical Encoder Guide High Resolution Applications and Selection

Explore high-precision incremental optical encoders with superior resolution speed and reliability for industrial automation and motion control applications.

Read More

If you’re on the hunt for a reliable incremental rotary encoders supplier, you already know how critical quality and precision are to your project’s success. Whether you’re an engineer, OEM, or procurement specialist, finding the right source for incremental rotary encoders means balancing exacting technical specs with competitive pricing and fast delivery. In this guide, you’ll discover everything you need to confidently choose suppliers who deliver robust performance, customization options, and the dependable support your operation demands. Let’s get straight to the essentials that will streamline your search and secure the best fit for your industrial automation needs.

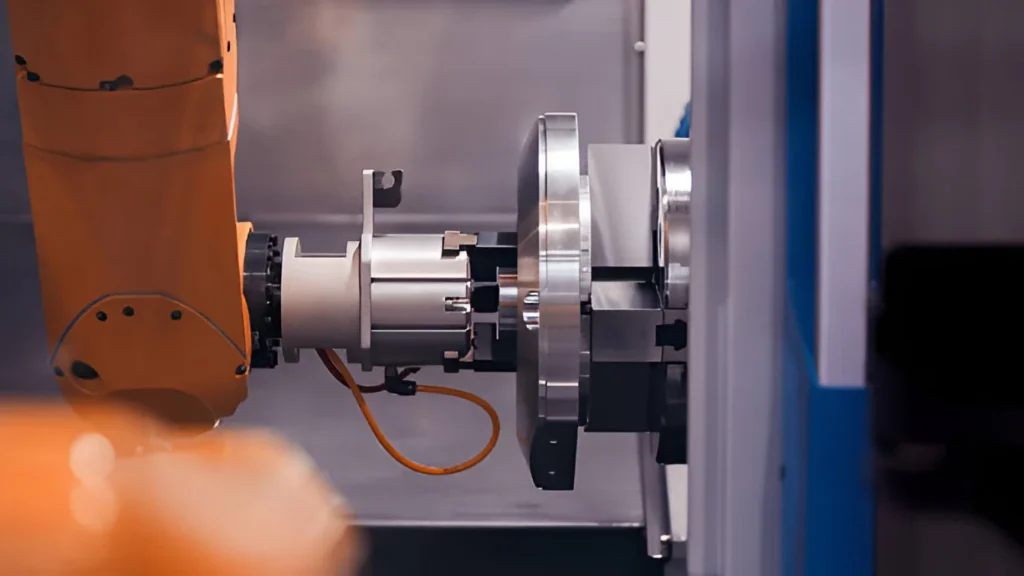

Incremental rotary encoders are essential position feedback sensors used widely in industrial automation, robotics, and machinery. They generate pulses as the shaft rotates, helping track speed, direction, and position in real time.

At the core, these encoders detect movement by converting mechanical rotation into electrical signals. The spinning shaft passes signals through either optical or magnetic sensing methods:

| Sensing Type | Description | Pros | Cons |

|---|---|---|---|

| Optical | Uses LEDs and photodetectors | High resolution, precise | Sensitive to dust and dirt |

| Magnetic | Uses magnetic sensors (Hall effect or magnetoresistive) | Durable, good in harsh environments | Slightly lower resolution |

When choosing an incremental rotary encoder, keep these specs in mind:

| Specification | What It Means |

|---|---|

| Resolution (PPR) | Pulses per revolution — defines positional accuracy |

| Output Signals | Typically quadrature signals (A, B), sometimes Z (index) |

| Shaft Types | Solid shaft or hollow shaft options tailored to your mounting needs |

The output signal type affects how the encoder interfaces with your control system:

| Signal Type | Characteristics | Use Cases |

|---|---|---|

| TTL | Transistor-Transistor Logic, standard voltage levels, suitable for low voltage systems | General industrial controls |

| HTL | High Threshold Logic, higher voltage levels, noise resistant | Harsh industrial environments |

| Push-Pull | Allows bidirectional switching, flexible integration | Versatile applications |

Proper mechanical and electrical mounting is critical for reliable encoder performance. Consider:

Understanding these basics helps you select the right incremental rotary encoder supplier who can meet your technical needs and application requirements.

When choosing an incremental rotary encoder, understanding its IP rating and environmental resistance is crucial. The IP (Ingress Protection) rating tells you how well the encoder is sealed against dust, moisture, and water. For industrial or outdoor use, a minimum of IP65 is often recommended to ensure the encoder withstands harsh conditions without performance loss.

Another key factor is the maximum rotational speed and frequency response—these specs determine how fast and accurately your encoder can track motion. Heavy-duty incremental encoders should handle high speeds while maintaining signal clarity.

Make sure to also consider the environmental standards the encoder meets, such as resistance to chemicals, vibration, and temperature extremes. These factors directly impact long-term reliability, especially in tough working environments.

For a deeper dive into environmental factors affecting incremental encoders, check out this detailed guide on what environmental factor should you consider choosing an incremental encoder.

When choosing a reliable incremental rotary encoder supplier, product longevity and consistent performance should be top priorities. A good supplier must offer customization options, including various shaft types like solid or hollow shafts, and different connector choices to fit your application perfectly. Look for suppliers who have strong manufacturing capabilities—this ensures they can handle custom OEM rotary encoder orders and deliver to your exact specs.

Global quality certifications such as ISO 9001 or CE mark indicate the supplier’s commitment to high standards and product reliability. Pricing tiers matter too; a trustworthy supplier balances cost and quality without cutting corners on key components, especially for industrial rotary encoder applications where durability is critical.

Lead times and supply chain stability are essential for avoiding downtime. Suppliers with steady production lines and good inventory management reduce delays, ensuring you receive replacement incremental rotary encoders or new products when needed without hassle.

For example, Sensyor provides strict quality control, offers a wide range of encoder models, and supports customization to meet your specific needs—all while maintaining short lead times and reliable delivery. Check out Sensyor’s GLT8030B incremental rotary encoder for a device known for long-term durability in demanding environments.

When looking for a reliable incremental rotary encoders supplier, it helps to know the key players and what they offer. Below is a quick overview of popular brands, service terms, and what to watch out for when choosing between distributors and factory-direct suppliers.

| Supplier Brand | Strengths | Warranty & Service | Notes |

|---|---|---|---|

| Baumer | High precision, wide selection | Standard warranties, solid support | Strong after-sales assistance |

| Dynapar | Heavy duty encoders, custom options | Extended warranties available | Focus on industrial motors |

| EPC | Competitive pricing, flexible lead times | Good customer service | Accessible for small orders |

| Pepperl+Fuchs | Robust design, environmental rating focus | Premium support packages | Often favored for harsh environments |

| POSITAL | Innovative OEM solutions, optical & magnetic | Comprehensive warranty | Strong global presence |

For a detailed technical market overview and support options, check out our guide on incremental rotary encoder applications in industrial automation.

Choosing the right supplier sets the stage for reliable, long-lasting position feedback sensors tailored to your application.

Sensyor stands out as a trusted incremental rotary encoders supplier thanks to its strong manufacturing capabilities and customer-focused approach. We offer a wide range of models, from solid shaft rotary encoders to hollow shaft incremental encoders, designed to meet diverse industrial needs. Our products are built tough for reliability and precision in demanding environments.

| Feature | Benefit |

|---|---|

| Robust Product Designs | Durable encoders suitable for heavy-duty applications |

| Strict Quality Control | Ensures consistent performance and longevity |

| Fast Lead Times | Quick delivery to keep your projects on schedule |

| Customization Options | OEM rotary encoders tailored to specific shaft types, connectors, or output signals |

| Real-World Success | Proven performance in industrial and harsh environments |

| Dedicated Support | Expert guidance from selection to after-sales service |

Sensyor’s focus on quality is backed by rigorous in-house testing, ensuring every encoder meets strict standards. We provide multiple output signal types, including encoder with HTL output and quadrature signals, to fit your exact application needs.

For more on our robust product lineup and technical advantages, explore our GOT58FO4 Rotary Encoder or GLT58 Series Rotary Encoder.

Choosing Sensyor means partnering with a supplier who understands practical challenges and delivers reliable incremental precision encoders with quick turnaround and customization. Whether you need a standard or custom OEM rotary encoder, Sensyor is equipped to support your project from start to finish.

When choosing an incremental rotary encoder, clear steps help you find the right fit for your application. Here’s a simple guide to follow:

| Shaft Type | Key Benefits | Typical Use Case |

|---|---|---|

| Solid Shaft | Stronger, robust mounting | Heavy-duty, industrial machines |

| Hollow Shaft | Easier mounting, reduces weight | Robotics, lightweight equipment |

Explore more about incremental shaft encoder options to see which fits your setup.

Following these steps ensures you pick the best incremental rotary encoder for your needs, balancing performance, durability, and cost. For detailed technical guidance, check out our complete incremental rotary encoder guide.

| Feature | Optical Encoder | Magnetic Encoder |

|---|---|---|

| Accuracy | Very high | Moderate |

| Environmental Suitability | Sensitive to dust & dirt | Resistant to contaminants |

| Cost | Generally higher | Usually more affordable |

| Output Signals | Typically quadrature signals | Quadrature or other formats |

This FAQ covers critical points to help you confidently select your incremental rotary encoder from a reliable industrial rotary encoder supplier. For instance, our GOS58B05 rotary encoder range offers detailed specs to suit varying PPR and environmental needs.

When it comes to ensuring long-term reliability in harsh environments, choosing the right incremental rotary encoders supplier is crucial. Look for suppliers who offer heavy duty incremental encoders with robust IP ratings and proven environmental resistance. Key criteria include product quality, customization options, stable supply chains, and strong technical support.

A reliable incremental rotary encoder manufacturer should provide a wide range of models, including optical and magnetic types, with various shaft options and output signals to fit your application’s needs. Don’t overlook lead times, warranty terms, and service responsiveness when making your decision.

For expert guidance and top-quality encoders, contact Sensyor for professional consultation and competitive quotes. With a strong reputation for reliable products, fast delivery, and OEM customization, Sensyor stands out as a trusted global industrial rotary encoder supplier ready to support your projects.

Explore detailed selection advice in our how to choose the right encoders for your B2B project guide to get started with confidence.