As a professional incremental encoder supplier, Sensyor is committed to providing high-quality, high-performance encoder solutions for industrial automation customers. This article will provide an in-depth introduction to the classification, functions, product advantages, and frequently asked questions about incremental encoders, helping you better understand and select the right incremental encoder to improve your equipment’s precise control and operational efficiency.

What is an Incremental Encoder?

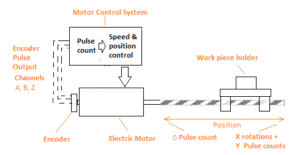

An incremental encoder is a sensor that detects the position and speed of a rotating shaft by outputting pulse signals. By counting the incremental changes in pulses, it reflects the real-time motion status of mechanical shafts. Incremental encoders are widely used in CNC machines, robots, automated production lines, and other fields, making them an indispensable component in industrial automation.

Compared to absolute encoders, incremental encoders have a simpler structure and lower cost but require a homing operation at startup to determine the initial position. Their output signals typically include two quadrature pulses (Channel A and Channel B) and a reference pulse (Channel Z), supporting direction detection and speed measurement.

Classification of Incremental Encoders

Incremental encoders are mainly divided into two categories:

- Optical Incremental Encoders

These use optical principles, where a light source and photodetector read a code disc with transparent and opaque areas to output precise pulse signals. Optical encoders offer high resolution and are suitable for high-precision applications.

- Optical Incremental Encoders

- Magnetic Incremental Encoders

These detect changes generated by a rotating magnet using magnetic induction principles. They have a more robust structure and strong anti-interference capability, making them suitable for harsh environments.

- Magnetic Incremental Encoders

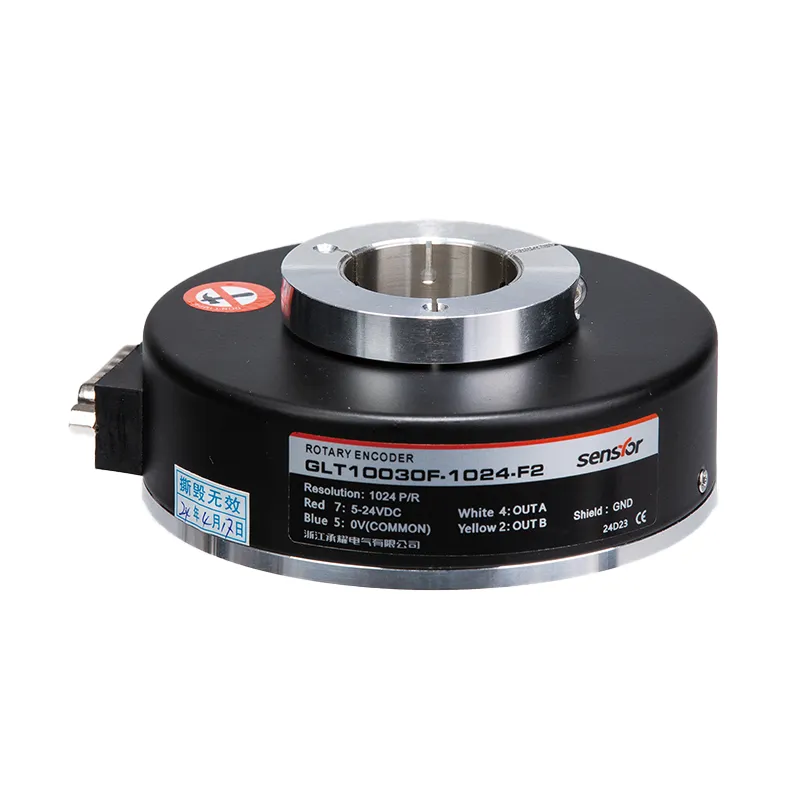

Additionally, incremental encoders can be further classified by mounting style and output signal type, such as shaft type, hollow shaft type, and flange-mounted models, meeting diverse industrial equipment needs.

| Category | Features | Typical Applications |

|---|---|---|

| Optical Encoder | High resolution, high precision, suitable for clean environments | CNC machines, precision instruments |

| Magnetic Encoder | Strong anti-interference, durable, suitable for harsh environments | Robots, heavy industrial equipment |

| Cable-saving Encoder | Simplified wiring, easy installation, cost-effective | Automated production lines, packaging machinery |

Core Functions and Technical Advantages of Incremental Encoders

The main functions of incremental encoders include:

- Position Detection: Determines the relative position of the shaft by counting pulses.

- Speed Measurement: The pulse frequency reflects the rotational speed.

- Direction Detection: The phase difference between Channel A and Channel B pulses identifies rotation direction.

- Reference Point Calibration: The Channel Z pulse serves as a mechanical zero-point calibration mark.

Technical advantages:

- High Resolution: Supports from hundreds to tens of thousands of pulses per revolution, meeting various precision requirements.

- Multiple Output Signals: TTL, HTL, RS422, etc., compatible with diverse control systems.

- Anti-Interference Design: Differential signal output improves signal stability.

- Flexible Channel Configuration: Dual or triple channel design ensures accurate direction and position feedback.

Sensyor Incremental Encoder Product Advantage

Independent R&D and Leading Technology

We own proprietary optical and magnetic encoder technologies to ensure product accuracy and stability.

Diverse Product Line

Offering various specifications and mounting options to meet different industrial applications.

High Protection Ratings

Products with IP65 or higher protection levels, suitable for dusty, humid, and harsh environments.

Excellent Durability and Reliability

Made from high-quality materials and rigorously tested to ensure long-term stable operation and reduced maintenance costs.

Flexible Customization Services

Customizable resolution, signal output, and mechanical interfaces to help customers achieve optimal solutions.

Comprehensive After-Sales Support

Professional teams provide technical consultation and quick response to ensure worry-free use.

Integration Advantages with PLCs and Servo Drives

In modern industrial automation systems, the close integration of incremental encoders with PLCs (Programmable Logic Controllers) and servo drives is key to achieving precise control. Sensyor incremental encoders offer the following integration advantages:

- Seamless Compatibility with Mainstream Control Devices

Supporting TTL, HTL, RS422, and other industrial standard signals, making it easy to interface with various PLCs and servo drives, reducing system modification costs. - Real-Time High-Speed Feedback

High-resolution pulse output ensures the control system obtains accurate position and speed information in real-time, improving motion control response speed and precision. - Simplified Wiring and Cost Reduction

Cable-saving design reduces the number of cables, lowers installation complexity and maintenance difficulty, and enhances overall system stability. - Support for Multiple Communication Protocols

Compatible with industrial protocols such as BiSS and SSI, facilitating integration into smart manufacturing and Industry 4.0 systems. - Improved System Reliability

Differential signals and anti-interference design ensure stable signal transmission, avoiding production errors caused by signal loss.

This tight integration not only enhances equipment performance but also saves customers significant time and costs. If you are looking for incremental encoders that perfectly match your PLC and servo drives, Sensyor is your ideal choice.

FAQ

What is the difference between incremental and absolute encoders?

Incremental encoders output relative position signals and require homing to establish the initial position. Absolute encoders output a unique absolute position value and retain position information even after power loss.

How to choose the right encoder resolution?

Higher resolution means more precise measurement but also higher cost and signal processing requirements. Choose based on your equipment’s control accuracy needs and budget.

How does an incremental encoder detect rotation direction?

By detecting the phase difference between Channel A and Channel B pulses. Channel A leading Channel B indicates one direction; the opposite indicates the other.

How do incremental encoders ensure stability in harsh environments?

Sensyor uses high protection ratings and anti-interference circuits to ensure stable operation in dusty, humid, and vibration-prone environments.

What output signals do Sensyor incremental encoders support?

They support TTL, HTL, RS422, and other industrial standard signals to meet different control system requirements.

How to properly install and debug an incremental encoder?

Ensure axial and radial runout are within allowable limits during installation, connect cables correctly.